In the modern age of manufacturing, Computer Numerical Control (CNC) machines have transitioned industries to automated, precise and consistent production techniques. CNC machines offer unparalleled precision, speed and repeatability through their coded instructions, ensuring high quality at a scale and speed previous methods could not achieve. They now form a critical backbone for industries ranging from aerospace to consumer goods. The rise in product complexity increased demand for CNC machines tailored to specific applications, and bridge mills are one breakout machine that has become instrumental in meeting the dynamic and fast-paced challenges of multiple industries.

Understanding Bridge Mills

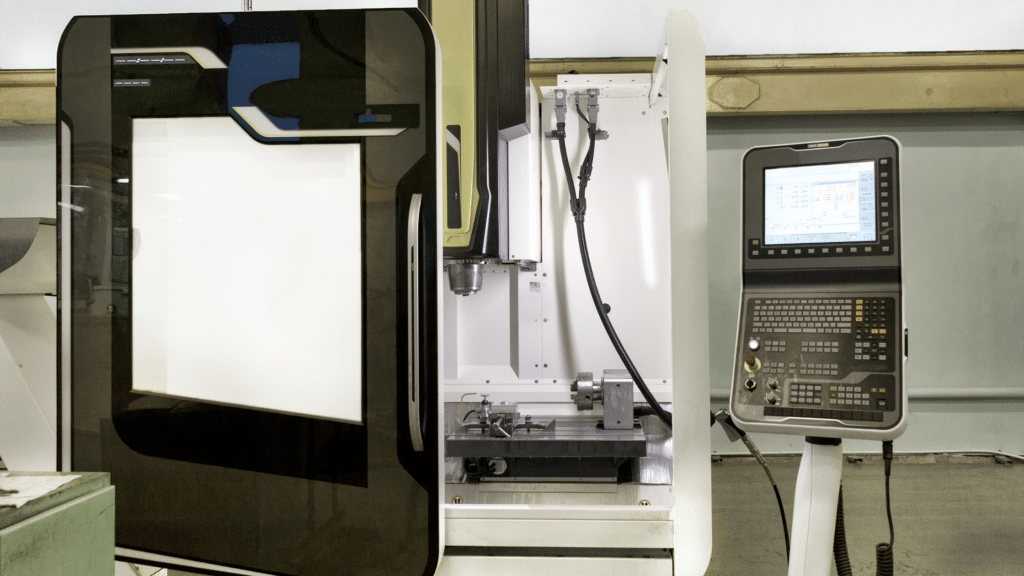

A bridge mill is a Vertical Machining Center (VMC). VMCs are a type of CNC machine with a vertically-oriented spindle axis. Unlike horizontally-oriented CNC machines, this vertical arrangement allows for more efficient cutting and a more compact machine design.

As a VMC, the bridge mill is characterized by its extended Y-axis, which is fully supported. Unlike cantilever machines, the bridge mill’s distinguishing feature is the construction of its base, to which a one-piece bridge structure is bolted. The X-axis runs along the length of the bed, while the Y-axis is along the bridge structure.

While there are multiple types of vertical machining centers like L-frame and C-frame, bridge mills stand out because they aren’t restricted by the Y-axis travel limitation that other vertical machining centers often face.

The Advantages of Bridge Mills

The design of bridge mills offers various advantages over other vertical machining centers.

One of the key attributes making bridge machines indispensable is their extended work envelope, which permits longer Y-axis travel. This longer axis allows for the production of much larger and longer parts than a traditional vertical CNC machine. Their versatility offers a practical solution to oversized double-column and smaller 3-axis machines.

Equipped with powerful spindle motors with high torque, bridge mills can cut through tough materials at impressive speeds, optimizing the manufacturing process. Their unique construction provides extreme stability for precise milling requirements critical to the aerospace, automotive and die/mold manufacturing industries.

The secret to the bridge mill’s success is found in its build.

Their design, characterized by the fully supported Y-axis, absorbs cutting vibration, ensuring enhanced rigidity. This rigidity is imperative for high-speed machining applications and for working with challenging materials, such as superalloys or hardened steels.

Should You Buy a Bridge Mill or C-frame VMC?

C-frame vertical machining centers have their own advantages and are extremely popular due to their affordability. However, bridge mills stand out in terms of performance. Their superior rigidity and thermal stability mean bridge mills generally surpass a similarly sized C-frame in machining parts that demand tight tolerances or exceptional surface finishes.

Although C-frames are usually a less expensive option, bridge mills often offer a more efficient and cost-effective solution when viewed as a long-term investment.

Explore Your Bridge Mill Options with Accurate Machine Tool Services

While multiple milling technologies are available to meet diverse industrial needs, bridge mills stand out due to their design, precision and versatility. At Accurate Machine Tool Services (AccurateMTS), we know choosing the right machine impacts your operational efficiency and bottom line. With all the complex options on the market, optimizing your CNC and VMC choices is the key to success.

AccurateMTS’s skilled team has over 100 years of combined sales, repair and maintenance experience on all makes and models of CNC machines. We can use our extensive knowledge base to provide you with expert guidance on selecting and optimizing your CNC and VMC performance. Contact us today and discover how a CNC bridge mill can revolutionize your production.