Electrical Repair

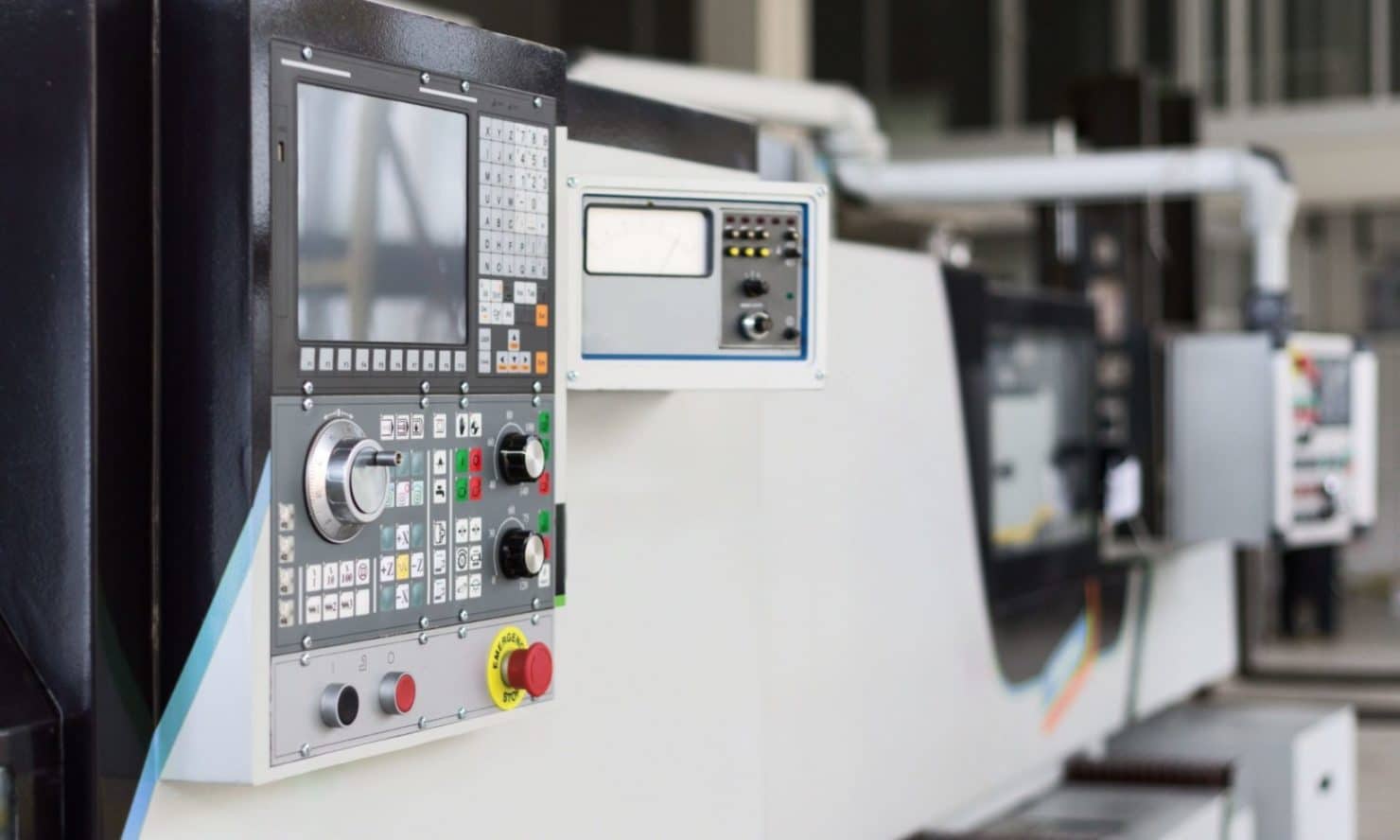

CNC Electrical Repair Services

Do not lose customers, employees, and money with electrical problems.

When your machine is down, Accurate won’t let you down! Their skilled and experienced technicians can handle a wide variety of CNC electrical repair problems with accurate diagnostics and effective repair solutions to put your production back on-line quickly and efficiently.

CNC machines depend on the smooth, even, and safe flow of electricity to operate correctly and perform their tasks with the expected accuracy and quality. Electrical fluctuations, spikes, and outages can damage your expensive CNC machines and ruin costly materials. Accurate Machine Tool Services’ technicians are fully qualified, knowledgeable, and equipped with everything necessary to perform CNC electrical repairs at your location.

Get your machine back online in record time!

- Brittle cables can cause problems – they can replace it, even if you cannot discern the cable information.

- Voltage drops can cause serious damage to expensive machinery – they can perform thorough system testing to determine the cause and create a solution.

- Intermittent failures cause expensive interruptions to production – their skilled techs can find the problem and solve it quickly and safely.

- Don’t worry about downtime while waiting for parts – they have many standard components for numerous brands of machinery in stock and ready for shipment or installation.

Accurate has the skills and knowledge to repair your machinery from these top manufacturers, including but not limited to:

- NTC

- NAKAMURA TOME

- KIA

- OKK

- MATSURA

- ROBO DRILL

- YOUJI

- JOHNFORD

- HITACHI SEIKI

- Hurco

- Kitamura

- Smec

- Eurotech

- TOYODA

- HYUNDAI

- WIA

- MORI SEIKI

- HWACHEON

- AWEA

- KIWA

- TOPPER

- SAMSUNG

- Leadwell

- Milltronics

Qualified CNC Electrical Services with Popular Manufacturers

The skilled technicians at Accurate Machine Tool Services boast over 100 years of combined experience in all manner of CNC electrical services, and bring that vast collection of know-how to help your company when problems threaten to derail your productivity.

Electricity and Heat Causes Excessive Wear on Components & Equipment

Constant electrical current and the heat it generates causes more wear and tear on your equipment and its components than you may realize. With production moving at a steady pace, your machinery has little time to rest and cool down, and this includes the vital electrical components. Many of the wear-and-tear and/or heat-related electrical problems that are encountered include:

Problems with Multiple Power Supplies – many CNC machines are fed by more than one power supply, and most are 24VDC; some control circuits are 5 and 12VDC. Voltage draw-downs and/or blown fuses are typically the first indicator of a problem.

Low Voltage at the Machine or Device – when you experience low voltage at the machine but not at the source, the likely culprit can be loose terminals, crimped wiring, or a loose relay, coil, contactor, or brake. The machine will not operate or will operate intermittently and create excessive heat, particularly near the troublesome electrical components.

Electrical Shorts – many electrical shorts are caused by deteriorated cables, coils, or other components, usually due to lots of heat over time. Heat dries out and hardens many components, reducing their conductivity and insulating properties. Insulation deteriorates and cracks or flakes away, allowing electricity to escape.

Worn DC Motor Brushes – electricity causes wear over time, and contact brushes can wear out with constant use. Bright, shiny brushes are a sign of good contact; dull brushes are overly worn and making poor contact and should be replaced. Check the springs for wear and appropriate tension.

Experienced CNC Electrical Repair in Wisconsin

Electrical problems and breakdowns do not have to cost you lost time and loads of expense. Accurate Machine Tool Services in Franklin, WI provides professional, timely, and efficient CNC electrical repair when and where you need it. When your machine is down, Accurate won’t let you down! Call today at 262-662-1100 for CNC electrical repair on all makes and models of equipment.